In 1936, the very first produced world table (PCB) was developed by Henry Eisle. However it wasn’t before the 1950s once the U.S. Safety business started adding PCBs in their blast detonator methods that printed circuit panels discovered large application. PCBs are now actually used in almost all manufactured products such as for instance, automobiles, cellular phones, particular computers, among others.A Summary of the PCB Fabrication ProcessesPCBs are originally manufactured with the use of two kinds of software. Pc Served Design (CAD) application is employed to style the digital schematic of the signal to be produced. After the schematic was created, Computer Assisted Production (CAM) application is employed by technicians to make the PCB prototype.

When the PCB prototype is made, the first step in the manufacturing method is to choose the product of the printed circuit board. There are numerous several types of PCB resources available, but the favorite types, on the basis of the software and a customer’s demands, include: Alumina, Arlon, Bakelite, CEM1, CEM5, Ceramic, FR1, FR4, FR4 Large Temperature, GeTek, Nelco, Polyimide and Rogers.The design necessity dictates the measurements of the PCB (I.e., size, width and thickness).

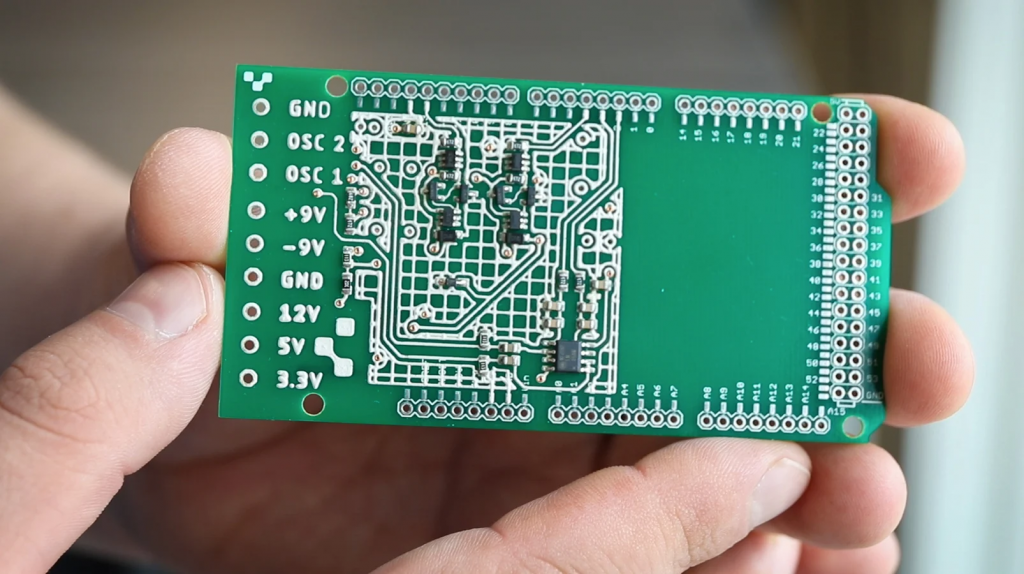

After the material has been picked, the first process is to utilize a covering of copper to the entire board. The enterprise layout will be printed on the table by a photosensitive process. Then, an image engraving process will be applied therefore that the copper that is perhaps not area of the world layout is likely to be etched out or taken off the board. The resulting copper creates the traces or paths of the PCB circuit. To get in touch the world traces, two functions are used. A technical milling process use CNC products to get rid of the pointless copper from the board. Then, an etch-resistant, silk-screen, making method is put on cover the parts where remnants must exist.

Now in the PCB fabrication method, the PCB panel contains copper records without any signal components. To mount the components, openings must certanly be drilled at the items where the electric and electronics areas are put on the board. The holes are drilled with sometimes lasers or even a special type of punch bit manufactured from Tungsten Carbide. Once the openings are drilled, worthless rivets are inserted into them or they’re coated by an electroplating method, which generates the electric relationship between the levels of the board. A masking product is then applied to fur the entire PCB with the exception of the patches and the holes. There are various types of masking product such as for example, cause solder, lead free solder, OSP (Entek), deep/hard gold (electrolytic nickel gold), engagement gold (electroless dime silver – ENIG), wire bondable gold (99.99% pure gold), concentration magic, flash gold, concentration tin (white tin), carbon printer, and SN 100CL, an combination of container, copper, and nickel. The ultimate part of the PCB manufacture process is to monitor printing the table so labels and the tale look at their proper locations.

Testing the Quality of the PCB Board

Prior to placing the electric and electric components on the PCB, the panel should be tried to validate their functionality. Generally, you will find two kinds of malfunctions that can create a defective PCB: a brief or an open. A “short” is a relationship between two or more circuit factors that will perhaps not exist. An “open” is really a stage the place where a relationship should occur but does not. These problems should be adjusted prior to the PCB is assembled. However, some PCB makers do not check their panels before they’re delivered, which can lead to issues at the customer’s location. So, quality testing is a critical means of the PCB manufacturing process. Testing guarantees the PCB boards are in appropriate working issue prior to element placement.

When developing a new service, or revising a preexisting one, designing and getting a model of the Printed Circuit Board (PCB) is frequently a difficult and expensive task. When we study why this is so, we shall discover ways to help make the method easy.

Like any other item that’s created to your specification, a new printed enterprise board has some up front prices which can be the same regardless of how big, or small the creation quantity is. To style a new board, or change an existing one, will have an engineering cost. There is likewise a cost to creating a new solder mask for the newest board. Remember whether you modify one element or you fully overhaul the table, any vary from an already paid for solder disguise, will demand a brand new anyone to be made.

It is just a frequent misconception that a little change in the PCB, should have a tiny demand to understand this change. As you see, a change is just a change regarding the expense of making the board. In addition, it does not follow for the engineering. It is usually the situation that someone has a product designed years ago by one engineer that they need slightly altered by yet another engineer. The brand new engineer will have to review the present style to see how better to implement the specified change.This can be annoying to the company paying the bill as they can feel cheated to pay for nearly the cost of a new PCB when they would like to change their active PCB.The way about this really is to strategy ahead when you are developing PCB from damage and work with a firm that will allow you to do this.Let’s take the exemplory instance of a PCB that in addition to energy and an electric on gentle, may have 2 inputs and 2 outputs. It’s possibly, if improbable, that other functions are preferred for the next technology of the item, let’s say 4 inputs and 3 outputs and a display. The facts of this desired version aren’t to the forefront but it is sensible that another technology could take advantage of that, some time later on (this can be also years later).

Recall, there’s a repaired price to the solder disguise and the engineering time. The included price of engineering the long run desired features is minimal set alongside the charge of planning from scratch. Only while there is circuitry on your own PCB doesn’t mean you’ve to populate it when you yourself have boards made. You are able to in essence make a table that has two revisions.While it’s true you will however have to make change to the application in your microcontroller, this will be easier and cheaper than revising the whole board.This will soon be particularly so in the event that you hold excellent records on the table and an excellent duplicate of the software with records to where you intend to change it.When you are seeking to own PCB developed and developed, choose a organization that will help you work through these issues. Use their expertise to see what is realistic to arrange for and what is not. If the company you will work with does not want to assist you with this specific; search for yet another one that does.

When it comes to choosing a contract producer to outsource your printed circuit table (PCB) assembly jobs, you will find eight parts to take into account when deciding upon the optimal PCB Assembly business:

- Spot: Choosing a contract maker that’s inside a drivable distance from your business gives you more freedom and agility to adapt to adjusting problems specially each time a contract is imminent. A PCB assembly company that is in your local area is easier when site surveys must be done and each time a lack of products and components occurs.

- Functionality of Production Gear: The efficiency of the production gear of a PCB contract company is crucial for their capability to fulfill the contract’s requirements. Do they have new or useless equipment? Will be the pick-and-place devices, reflow ovens, and trend soldering equipment well preserved? Researching their maintenance logs may provide you with the self-confidence that the company is serious about quality. This builds confidence in the commercial partnership.

- Assembly Staff Certifications: To guarantee the PCB contract assembler can total your production run on routine requires not only well preserved equipment, but additionally a certified team of construction technicians. So, review the training and certification documents of the assembly staff. Ensure they have received the specialized references allow them to do their given tasks. For anyone personnel who’re not certified, check on the development in the qualification process

- Quality Methods: Does the construction business have a quality system in position such as for instance ISO 9001:2008? This must be the minimal motherboard PCB gained by the company to make certain they are able to supply an excellent what is pcba board . If it’s still another quality program in place, is the company presently qualified by an authorized registrar? Finally, might the PCB assembly organization recognize to invest in getting qualified to the exact same quality system as your organization? In so doing, it means the business is committed to a long-term organization connection with you.

- Shipping Deadlines: The ability to meet shipping deadlines is a critical full for you really to establish if a contract producer has the capability, personnel and sources to meet your company needs. When probable, acquire documents from the PCB company regarding their power to generally meet deadlines. Obtain a detailed knowledge of who is manufacturing the PCBs and wherever they are produced.

- Elements Procurement: Perform analysis their procurement department. Do they maintain an adequate in-house stock? Are their companies local, local, or geographically varied and what is the type of the vendor relationships? Are the associations shut enough in a way that cost savings can quickly be passed down to you? How can their procurement division deal with hard-to-fine or obsolete elements? Do they have procurement specialists who’ve expertise in sourcing replacement components for useless pieces? Can they take your schematics/drawings and create a Statement of Materials with little or no guidance by you?

- Charge Efficient Pricing: Since job prices range, you must receive an itemized break down of the sum total price of manufacturing. Verify what’s included in the manufacturing costs. Then you definitely must perform a cost contrast examine to determine if their costs are commensurate with a average and their competitors. Ensure you’ve and precise comparison of charges and the bottomline price.